Precision Automation Products

Formerly Delta Sigma Automation; we are the leading supplier of Automation Products in the Southeastern United States

Tariff Policy Update

There is now a 10% Tariff surcharge on all HIWIN products. This surcharge will be reflected at the Cart and Checkout.

Purchase Directly

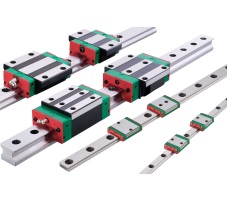

Purchase Genuine HIWIN Linear Guideway Blocks and Cut-to-Order Linear Guideway Rail. Click the desired HIWIN Guideway product series to start configuring to your specifications and order directly through our website!

Purchase via Quote

Allow us to quote for your needs for other Automation Products by clicking the categories below. Our website will assist you in populating a list for quotation.